The Renishaw QC20-W ballbar system consists of:

In use the balls of the sensor are kinematically located in the magnetic cups. This arrangement enables the ballbar to measure minute variations in radius as the machine follows a programmed circular path around the mount on the machine table.

The data collected is sent to a PC, where Renishaw's software calculates overall measures of positioning accuracy (circularity, circular deviation) in accordance with international standards such as ISO 230-4 and ANSI/ASME B5.54 or in Renishaw's own analysis reports. This report uses a unique mathematical analysis to diagnose many additional individual machine errors from the set of linear readings. Data is displayed graphically as well as in numeric format to aid and support diagnosis.

More information on how ballbar works can be found on our Ballbar testing explained web page.

Ballbar testing provides a simple, rapid check of a CNC machine tool's positioning performance to recognised international standards (e.g. ISO, ANSI/ASME etc) allowing users to benchmark and track the performance of their machines and to quickly diagnose problems that may require maintenance and the error sources that produce them.

Regular ballbar testing of machine tools helps to:

Why use a Renishaw QC20-W ballbar? provides more information on the benefits of implementing Renishaw ballbar testing into your manufacturing processes.

The QC20-W system draws on Renishaw's many years of experience with ballbar testing and offers significant performance and operational benefits:

The standard QC20-W ballbar kit includes a 100 mm long ballbar assembly and 50, 150 and 300 mm long extension bars. By assembling the ballbar with different combinations of extension bars it is possible to carry out ballbar tests with 100, 150, 250, 300, 400, 450, 550 or 600 mm radii.

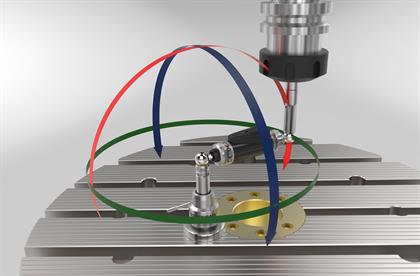

Redesigned ball mounts (including new centre pivot and tool cup extension) allow the QC20-W to carry out additional 220° 'partial arc' tests in planes through the centre pivot axis. This means that you can now carry out ballbar tests in three orthogonal planes without the need to reposition the centre pivot, so speeding up testing (if carrying out 'partial arc' tests with a radius greater than 150 mm custom fixturing is required).

The results can also be used in the new 'volumetric analysis' report function (see Ballbar 20 software) with the assurance that all data has been gathered around the same point.

QC20-W ballbar can be used in conjuction with Ballbar Trace a new time-based software package. Ballbar Trace's flexible use opens up QC20-W to many new applications, including 5-axis ballbar verification (to ISO 10791-6) and static monitoring. The new software is free of charge to existing QC20-W users.

The standard QC20-W kit comes in its own robust carry case which includes the QC20-W wireless ballbar, battery, spindle and table mounts (pivots), 50 mm, 150 mm and 300 mm ballbar extensions (to allow various test diameters) and tools.

Ballbar 20 software and manual are supplied on a single CD with a 'Getting started' video guide provided on a separate DVD.

Also included is a calibrator for enhanced test analysis. (It enables absolute readings for scale errors and a handy means of checking that the ballbar is reading nominally correctly).

Fully traceable calibration certificates for the ballbar and calibrator, and validation labels to display test results on machines are also included in the kit.

Every QC20-W ballbar kit includes the 'Getting started with QC20-W ballbar' DVD which introduces the system, then takes you step-by-step through the set-up, installation and use of the system, showing you how to carry out a test and review the results. The DVD is available, free of charge, from your local Renishaw office or can be viewed on our Training videos page.

Expand the versatility of the QC20-W ballbar by including lathes in your ballbar test programs. Diagnosing specific errors on your lathe is both quick and easy using this accessory.

Lathe adaptor kit includes: